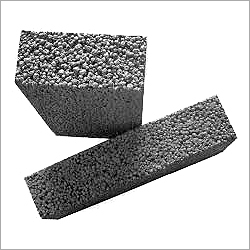

Industrial Autoclaved Aerated Concrete Block

Industrial Autoclaved Aerated Concrete Block Specification

- Drying Shrinkage

- <0.2 mm/m

- Carbonation Coefficient

- Low

- Length

- 600 mm

- Oftening Coefficient

- 0.8

- Moisture Content

- Below 8%

- Cavity

- Solid (no internal cavity)

- Water Absorption

- Less than 30%

- Dry Density Grade

- 400-700 kg/m

- Thickness

- 100 mm

- Method

- Autoclaving

- Material

- Autoclaved Aerated Concrete (AAC)

- Compressive Strength

- 3.5-7 MPa

- Usage & Applications

- Interior and exterior wall construction, partitions, industrial buildings

- Density

- 600 Gram per cubic centimeter(g/cm3)

- Width

- 200 mm

- Strength

- High structural strength for load-bearing walls

- Frost Resistance

- High, suitable for cold climates

- Porosity

- High, approx. 75% voids

- Thermal Conductivity

- 0.15 W/mK

- Type

- Industrial Autoclaved Aerated Concrete Block

- Color

- Greyish White

- Size

- 600 x 200 x 100 mm

- Weight

- Approx. 18-24 kg/block

- Shape

- Rectangular Block

Industrial Autoclaved Aerated Concrete Block Trade Information

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- Piece

- Delivery Time

- Week

- Sample Available

- Yes

- Sample Policy

- Within a certain price range free samples are available

- Main Domestic Market

- North India

About Industrial Autoclaved Aerated Concrete Block

With the rich expertise of our team members, we are competent to manufacture and trade a finest quality array of Industrial Autoclaved Aerated Concrete Block in the domestic market. These concrete blocks are ideal for construction of any type walls or floors at various residential and commercial buildings. Available in various designs, sizes and finishes to suit the individual needs of the clients, this Industrial Autoclaved Aerated Concrete Block is made using the best quality material.

Features

- Resistant to Fire

- Sound Reduction

- Sleek designs

Further Details

| Type | Length | Height | Thickness |

| Block | 625mm | 250mm | 100mm to 300mm with an increment of 25mm |

| Properties | Values |

| Density ( Oven Dry ) | 551-650 kg/m3 400mx250mx100m |

| Compressive Strength As Per IS | 2185 Part 3 400mx250mx150m |

| Thermal Conductivity | 0.16 W/M deg.K (Average) 400mx250mx200m |

| Resistant To Fire | 2-6 Hrs Depending Upon Thk 525mx250mx100m |

| Sound Reduction Index | 37-49 db Depending Upon Thk 525mx250mx150m |

| Design Density | 800 kg/m3 525mx250mx200m |

Fire Resistance for Safety

AAC blocks provide up to 4 hours of fire resistance, meeting strict safety standards and ensuring reliable protection in industrial settings. This property makes them a preferred choice for environments where fire safety is paramount, from factories to warehouses. Their inherent composition prevents the spread of flames and maintains structural integrity during fire incidents.

Superior Sound Insulation

Thanks to their high porosity and dense structure, AAC blocks offer excellent acoustic properties. They significantly reduce noise transmission, making them ideal for partitions, office walls, and separating noisy production areas. This sound insulation enhances workplace comfort and productivity by minimizing disturbances.

Eco-Friendly and Sustainable

Manufactured using recyclable and environmentally sustainable materials, AAC blocks contribute positively to green building initiatives. Their production method and long-lasting durability ensure reduced carbon footprints, while the blocks are free from toxic substances. Choosing AAC blocks supports responsible construction practices and compliance with sustainability standards.

FAQs of Industrial Autoclaved Aerated Concrete Block:

Q: How are AAC blocks installed on construction sites?

A: AAC blocks are lightweight and easy to handle, allowing quick installation. They can be cut or drilled as needed with basic tools. After placement, the smooth surface is ready for direct plastering or painting, reducing finishing time.Q: What benefits do AAC blocks offer in industrial applications?

A: These blocks deliver high structural strength for load-bearing walls, moderate impact resistance, excellent seismic performance due to their lightweight, and top-tier fire and sound insulation, making them suitable for demanding industrial environments.Q: When should AAC blocks be used over traditional bricks?

A: AAC blocks are recommended when fire resistance, sound insulation, eco-friendliness, and rapid installation are crucial. They outperform conventional bricks where insulation and sustainability are priorities, such as in industrial buildings and partitions.Q: Where can AAC blocks be applied in building projects?

A: AAC blocks are versatile and suitable for both interior and exterior wall construction, partitions, and industrial building facades. Their durability and excellent resistance to frost and efflorescence make them ideal for various climates and locations.Q: What is the manufacturing process of AAC blocks?

A: AAC blocks are produced by autoclaving a mixture of cement, lime, sand, and aluminum powder. This creates a lightweight, high-porosity block with uniform dimensions, complying with IS 2185 (Part 3):1984 or equivalent international standards.Q: How does the eco-friendly nature of AAC blocks benefit construction?

A: AAC blocks are recyclable, have low embodied energy, and release minimal harmful substances. Their use supports sustainable building practices, reduces environmental impact, and can contribute to green certification of projects.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in AAC Blocks Category

Concrete AAC Rubble Blocks

Price Range 35.00 - 100.00 INR

Minimum Order Quantity : as per requremnt Piece

Size : 600 x 200 x 100 mm

Carbonation Coefficient : Low

Cavity : Solid

Dry Density Grade : 600750 kg/m

Broken Light Weight Blocks

Price Range 35.00 - 100.00 INR

Minimum Order Quantity : as per requrement Piece

Size : Approx 600 x 200 x 100 mm

Carbonation Coefficient : Low

Cavity : Solid

Dry Density Grade : 500 650 kg/m

Lightweight Concrete Block

Minimum Order Quantity : 50 Bags

Size : 600x200x100/150 mm (typical)

Carbonation Coefficient : Low

Cavity : With/without cavity options

Dry Density Grade : 500800 kg/m

ACC Rectangular Blocks

Size : 600 mm x 200 mm x (75300 mm)

Carbonation Coefficient : Low

Cavity : Solid

Dry Density Grade : 550 650 kg/m

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS