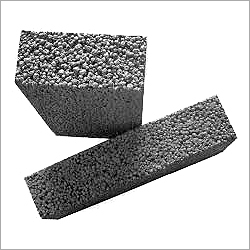

Lightweight Concrete Block

Lightweight Concrete Block Specification

- Frost Resistance

- High

- Type

- Lightweight Concrete Block

- Cavity

- With/without cavity options

- Carbonation Coefficient

- Low

- Thickness

- 100 to 200 mm (varies as per block size)

- Color

- Gray

- Method

- Autoclaved or Non-Autoclaved

- Water Absorption

- <30%

- Density

- 800 Gram per cubic centimeter(g/cm3)

- Length

- 400 to 600 mm

- Moisture Content

- <10%

- Oftening Coefficient

- 0.850.9

- Dry Density Grade

- 500-800 kg/m

- Porosity

- High (cellular structure)

- Width

- 200250 mm

- Material

- Lightweight Concrete (AAC/CLC/Similar)

- Usage & Applications

- Partition walls, Load bearing/non-load bearing walls, Interior and exterior applications

- Drying Shrinkage

- 0.040.06%

- Thermal Conductivity

- 0.120.18 W/(mK)

- Compressive Strength

- 3-5 MPa (varies by grade)

- Strength

- Standard as per IS:2185 (Part 3)

- Size

- 600x200x100/150 mm (typical)

- Weight

- 818 kg/block (depending on size)

- Shape

- Rectangular, Solid with possible Cavity

Lightweight Concrete Block Trade Information

- Minimum Order Quantity

- 50 Bags

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- Bag

- Delivery Time

- Week

- Sample Available

- Yes

- Sample Policy

- Within a certain price range free samples are available

- Main Domestic Market

- North India

About Lightweight Concrete Block

We are affianced in manufacturing and supplying an extensive assortment of Lightweight Concrete Block, which is manufactured by using premium quality of materials. Our offered fly ash bricks are appreciated by clients because it is highly suitable for long term use as a marine float device and highly cost effective. This Lightweight Concrete Block is widely used for complete wall casting, sound barrier walls, house casting, slope protection and outdoor furniture.

Features

- Available in different densities and strengths

- Light in weight

- Superior in quality

Further Details

Type | Length | Height | Thickness |

Block | 625mm | 250mm | 100mm to 300mm with an increment of 25mm |

Properties | Values |

Density ( Oven Dry ) | 551-650 kg/m3 400mx250mx100m |

Compressive Strength As Per IS | 2185 Part 3 400mx250mx150m |

Thermal Conductivity | 0.16 W/M deg.K (Average) 400mx250mx200m |

Resistant To Fire | 2-6 Hrs Depending Upon Thk 525mx250mx100m |

Sound Reduction Index | 37-49 db Depending Upon Thk 525mx250mx150m |

Design Density | 800 kg/m3 525mx250mx200m |

Light Weight Concrete also known as Foamed Concrete basically comprises of cement based mortar with at least 20% of volume air. This material is widely used in a number of applications from one step house casting to low density void fills. Being a free flow and lightweight material it is found highly suitable for many purposes such as complete house casting, wall casting, floor and roof screeds, sound barrier walls, slope protection, outdoor furniture etc.

- This type of concrete has relatively low strength but is supplemented through structural reinforcement.

- This type of concrete is superior in quality and also assures a specified density.

- Light Weight concrete can be used with any type of Portland cement.

- It offers the resilience to be manufactured in a wide range of densities and strengths.

- It is available in different densities and strengths.

- It is highly suitable for long term use as a marine float device.

- It is highly cost effective.

Exceptional Fire and Sound Protection

Engineered to offer fire resistance up to 4 hours and acoustic insulation between 3742 dB, these lightweight concrete blocks help create safer and quieter environments in any building. Their robust composition withstands high temperatures and significantly reduces noise transfer for enhanced comfort.

Accelerated Construction and Easy Installation

Lightweight Concrete Blocks speed up building processes and are simple to work with. Their structure permits effortless cutting, drilling, and fitting, accelerating construction compared to conventional brickwork. Compatibility with all mortars and plasters ensures versatility across various design and functional requirements.

Eco-Conscious and Durable Solution

Made with eco-friendly materials and a recyclable nature, these blocks minimize environmental impact. High frost resistance, minimal drying shrinkage, and robust compressive strength ensure long-lasting stability in both interior and exterior applications, even in extreme climates.

FAQs of Lightweight Concrete Block:

Q: How can Lightweight Concrete Blocks be installed in construction projects?

A: Lightweight Concrete Blocks are easily installed using standard building techniques. They are compatible with all types of mortars and plasters and can be cut or drilled as needed, allowing for precise fitting and faster construction compared to conventional bricks.Q: What are the main benefits of choosing Lightweight Concrete Blocks over traditional bricks?

A: Key advantages include superior fire resistance (up to 4 hours), sound insulation (37-42 dB), quick installation, and eco-friendliness. Their high frost resistance and smooth finish make them ideal for both interior and exterior partitions and load-bearing walls.Q: When is it recommended to use these blocks for load-bearing walls?

A: These blocks, with a compressive strength range of 35 MPa, are suitable for both load-bearing and non-load-bearing walls. Selection depends on specific structural requirements and block grade as per IS:2185 (Part 3) standards.Q: Where can Lightweight Concrete Blocks be applied in building design?

A: Their versatility makes them suitable for partition walls, load-bearing and non-load-bearing walls, as well as interior and exterior applications in residential, commercial, and institutional buildings.Q: What is the process for storing Lightweight Concrete Blocks before use?

A: It is important to store the blocks in dry conditions to maintain their quality. Proper stacking on pallets or protected surfaces helps keep moisture content low and prevents surface damage.Q: How does the eco-friendly aspect of these blocks contribute to sustainable construction?

A: The blocks are manufactured using recyclable materials with a low carbon footprint. This environmentally responsible approach supports sustainable building practices while offering durability and long-term performance.Q: What sizes and shapes are available for Lightweight Concrete Blocks?

A: Blocks come in rectangular solid or cavity shapes, with typical dimensions of 600x200x100/150 mm and thicknesses from 100 to 200 mm, allowing flexibility in various architectural and engineering applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in AAC Blocks Category

6 Inch AAC Blocks

Minimum Order Quantity : as per requrement Piece

Porosity : High

Dry Density Grade : 550650 kg/m

Usage & Applications : Partition & load bearing walls, residential & commercial construction, masonry works

Size : 600 x 200 x 150 mm

AAC Solid Block

Porosity : High

Dry Density Grade : 550 650 kg/m

Usage & Applications : Residential, Commercial, Industrial Buildings, Partition and Loadbearing Walls

Size : 600mm x 200mm x 100200mm

AAC Wall Blocks

Porosity : High (closed air pockets)

Dry Density Grade : 550 650 kg/m

Usage & Applications : Partition Walls, External/Internal Walls, HighRise Buildings, Apartments, Offices, Industrial and Commercial Structures

Size : 600 x 200 x (75/100/125/150/200) mm

AAC Fly Ash Block

Price 65 INR / Piece

Minimum Order Quantity : 100 Pieces

Porosity : required based

Dry Density Grade : required based

Usage & Applications : required based

Size : required based

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS