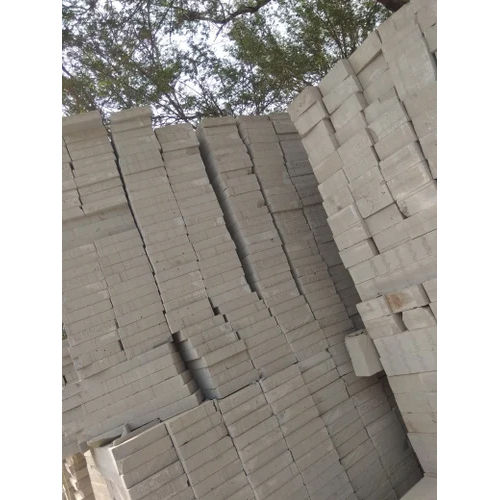

AAC Concrete Block

Price 3900 INR/ Cubic Meter

AAC Concrete Block Specification

- Oftening Coefficient

- required based

- Material

- Concrete

- Method

- Autoclaved Aerated Concrete

- Density

- 40 Kilogram per cubic meter (kg/m3)

- Dry Density Grade

- required based

- Carbonation Coefficient

- required based

- Moisture Content

- required based

- Thickness

- required based Feet (ft)

- Cavity

- required based

- Usage & Applications

- required based

- Compressive Strength

- required based Megapascals (MPa )

- Color

- Gray

- Thermal Conductivity

- required based Watt/Centimeter/C (W/(cm.C)

- Length

- required based Centimeter (cm)

- Type

- Concrete Block

- Frost Resistance

- required based

- Width

- required based Centimeter (cm)

- Porosity

- required based

- Weight

- required based Grams (g)

- Size

- required based

- Shape

- required based

AAC Concrete Block Trade Information

- Minimum Order Quantity

- 50 Cubic Meters

- FOB Port

- NEW DELHI

- Payment Terms

- Cash in Advance (CID), Cheque, Telegraphic Transfer (T/T)

- Supply Ability

- 100 Cubic Meters Per Day

- Delivery Time

- 1 Week

- Packaging Details

- As per requirement

About AAC Concrete Block

Birla Aerocon Blocks are likely related to building or construction materials. Aerocon is known for manufacturing lightweight autoclaved aerated concrete (AAC) blocks. These blocks are:

- Lightweight: Easier to handle and transport.

- Insulating: Provide thermal insulation for buildings.

- Eco friendly: Made with minimal environmental impact.

- Birla Aerocon is a brand that manufactures these AAC blocks for construction purposes.

FAQs of AAC Concrete Block:

Q: What are AAC Concrete Blocks and how are they manufactured?

A: AAC Concrete Blocks are made from concrete using the autoclaved aerated process, resulting in lightweight blocks with high porosity and thermal insulation. The material undergoes high-pressure steaming in autoclaves, which gives the blocks their unique cellular structure.Q: Where can AAC Concrete Blocks be used in construction projects?

A: These blocks are suitable for use in residential, commercial, and industrial buildings, especially for constructing walls, thermal insulation layers, partitions, and facades due to their customizable sizes and excellent mechanical properties.Q: How does the density and compressive strength of AAC Concrete Blocks benefit buildings?

A: A low density of 40 kg/m reduces the overall weight of the structure, while the required compressive strength in MPa ensures reliable load-bearing capacity, resulting in safer and more efficient buildings.Q: What process ensures the frost resistance and durability of these blocks?

A: Autoclaving creates a closed cellular structure which, combined with the required frost resistance parameters, helps the blocks maintain integrity and durability in harsh weather, safeguarding structures from freeze-thaw cycles.Q: When is it beneficial to use AAC Blocks over traditional concrete blocks?

A: AAC Concrete Blocks are highly beneficial when energy efficiency, lighter construction, and sound insulation are priorities, such as in multi-story buildings or eco-friendly architecture.Q: What are the thermal properties of these blocks and how do they help?

A: With a required thermal conductivity (in W/(cm.C)), AAC Blocks significantly reduce heat transfer, helping maintain comfortable indoor temperatures and lowering energy costs for heating or cooling applications.Q: Who manufactures and supplies AAC Concrete Blocks in India?

A: These blocks are produced and distributed by manufacturers and suppliers across India who provide a variety of options tailored to regional and project-specific requirements.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in BIRLA AEROCON BLOCKS Category

AAC Cement Block

Price 35 INR / Piece

Minimum Order Quantity : 50 Pieces

Density : 40 Kilogram per cubic meter (kg/m3)

Method : Autoclaved Aerated Concrete

Color : Gray

Material : Cement

Solid AAC Blocks

Price 3900 INR / Cubic Meter

Minimum Order Quantity : 50 Cubic Meters

Density : 40 Kilogram per cubic meter (kg/m3)

Method : Autoclaved Aerated Concrete

Color : Gray

Material : Cement

Aerated Autoclaved Block

Price 47 INR / Piece

Minimum Order Quantity : 50 Pieces

Density : 40 Kilogram per cubic meter (kg/m3)

Method : Autoclaved Aerated Concrete

Color : Gray

Material : Cement

50 mm AAC Block

Price 35 INR / Piece

Minimum Order Quantity : 50 Pieces

Density : 40 Kilogram per cubic meter (kg/m3)

Method : Autoclaved Aerated Concrete

Color : Gray

Material : Cement

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free