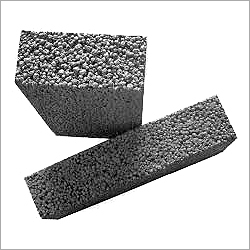

AAC Light Weight Blocks

AAC Light Weight Blocks Specification

- Oftening Coefficient

- 0.88

- Porosity

- 60-85%

- Material

- Autoclaved Aerated Concrete (AAC)

- Length

- 600 mm

- Frost Resistance

- High frost resistance, suitable for all climates

- Width

- 200 mm / 230 mm

- Thermal Conductivity

- 0.12-0.16 W/mK

- Carbonation Coefficient

- Low

- Strength

- 3-4.5 N/mm

- Water Absorption

- < 45%

- Color

- Light Grey

- Type

- AAC Light Weight Blocks

- Compressive Strength

- 3.0-4.5 Mpa

- Moisture Content

- 5-12%

- Drying Shrinkage

- 0.04-0.06%

- Dry Density Grade

- 550-650 kg/m

- Usage & Applications

- Residential, Commercial, Industrial construction, Partition & Load bearing walls

- Density

- 650 Gram per cubic centimeter(g/cm3)

- Cavity

- Solid

- Thickness

- 75 mm to 300 mm

- Method

- Autoclaving

- Size

- 600mm x 200mm x (75-300)mm

- Weight

- 8-25 kg depending on size

- Shape

- Rectangular Block

- Surface Finish

- Smooth and precise

- Shelf Life

- Indefinite when stored dry

- Eco-Friendliness

- Environment friendly, non-toxic, recyclable

- Fire Resistance

- Up to 4 hours

- Installation

- Quick and easy to handle and install

- Workability

- Easy cutting, shaping, and instant usage

- Pest Resistance

- Resistant to termites and other pests

- Alkalinity

- Highly alkaline (prevents corrosion)

- Sound Insulation

- Superior sound insulation, up to 45 dB

- IS Code Standard

- Conforms to IS 2185 Part 3

AAC Light Weight Blocks Trade Information

- Payment Terms

- Telegraphic Transfer (T/T), Cheque

- Sample Available

- Yes

- Main Domestic Market

- Delhi

About AAC Light Weight Blocks

Light weight Aac blocks are lightweight in comparison to the red bricks. These are functional as the unique as well as outstanding sort of building materials. These have resistance against heat, sound and fire. These are the lightweight blocks of durability, ultimate workability and flexibility. In addition, these have highest thermal rating. Utilization of the Light weight Aac blocks ensure the well-insulated interiors. They are protective against earthquake forces. The said blocks are offered with excellent resistance to the earthquake forces. Also, these can resist the high seismic activity.

Superior Fire and Sound Protection

AAC Light Weight Blocks deliver proven fire resistance up to 4 hours and advanced sound insulation up to 45 dB. These features make them ideal for buildings where safety and comfort are paramount. Their composition ensures peace of mind in both residential and commercial applications, offering a safer and quieter environment without compromising on structural strength.

Effortless Installation and Workability

Designed for convenience, AAC Light Weight Blocks can be easily cut, shaped, and instantly used on-site. Their lightweight nature allows for quick handling and installation, significantly reducing construction time and labor. With a precise and smooth surface finish, they support efficient construction, enabling both experienced builders and beginners to achieve professional results.

Eco-Friendly and Safe Choice

These blocks are manufactured using non-toxic, recyclable materials, making them a sustainable option for modern construction. They are resistant to termites, pests, and chemical corrosion thanks to their alkalinity. With high thermal insulation and frost resistance, AAC Light Weight Blocks maintain structural integrity and durability in all climatic conditions.

FAQs of AAC Light Weight Blocks:

Q: How are AAC Light Weight Blocks installed during construction?

A: AAC Light Weight Blocks are designed for quick and easy installation. They can be cut and shaped on-site using ordinary tools, making them simple to handle and fit. Blocks are laid using thin-bed mortar, reducing construction time and ensuring a strong bond between blocks.Q: What are the main benefits of using AAC Light Weight Blocks in building projects?

A: Key benefits include superior fire resistance (up to 4 hours), excellent sound insulation (up to 45 dB), ease of handling, high thermal and frost resistance, pest resistance, and environmental sustainability. They are also non-toxic, recyclable, and conform to IS 2185 Part 3 standards.Q: When should AAC Light Weight Blocks be used in construction?

A: AAC blocks are suitable for use in various phases of construction, particularly in walls that require fire and sound protection, such as partition and load-bearing walls. They are ideal for both new projects and renovations in residential, commercial, and industrial settings.Q: Where can AAC Light Weight Blocks be applied?

A: These blocks are widely used in residential apartments, commercial complexes, industrial buildings, and wherever sturdy, lightweight, and insulated construction materials are needed. They are suitable for internal and external walls, cavity walls, and infill structures.Q: What process is involved in manufacturing AAC Light Weight Blocks?

A: AAC blocks are created by combining natural raw materials, which are then autoclaved (cured under high-pressure steam). This process results in a highly porous yet strong and durable material with outstanding insulation properties and precise dimensions.Q: How do AAC Light Weight Blocks contribute to eco-friendly construction?

A: AAC blocks are made from non-toxic, recyclable materials and offer excellent energy efficiency due to their low thermal conductivity. Their high porosity and light weight reduce the overall material and energy usage during transportation and construction, lessening their environmental impact.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in AAC Blocks Category

3 Inch AAC Blocks

Price 55 INR / Piece

Minimum Order Quantity : 1000 Pieces

Shape : Rectangular

Cavity : Solid

Frost Resistance : High

Carbonation Coefficient : Low

6 Inch AAC Blocks

Minimum Order Quantity : as per requrement Piece

Shape : Rectangular

Cavity : Solid

Frost Resistance : Excellent

Carbonation Coefficient : Very Low

AAC Light Weight Block

Minimum Order Quantity : 100 Units

Shape : Rectangular

Cavity : Solid

Frost Resistance : Excellent, suitable for cold climates

Carbonation Coefficient : Low

Lightweight Concrete Block

Minimum Order Quantity : 50 Bags

Shape : Rectangular, Solid with possible Cavity

Cavity : With/without cavity options

Frost Resistance : High

Carbonation Coefficient : Low

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS