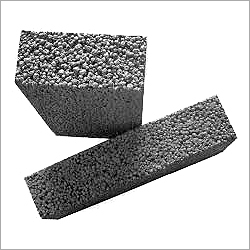

Construction AAC Broken Blocks

Construction AAC Broken Blocks Specification

- Oftening Coefficient

- 0.88

- Usage & Applications

- Construction, landfilling, sub-base, road construction, filler material

- Compressive Strength

- 3-4 MPa

- Thickness

- 75-150 mm

- Method

- Autoclaved

- Density

- Gram per cubic centimeter(g/cm3)

- Moisture Content

- 5-12%

- Carbonation Coefficient

- Low

- Cavity

- Solid

- Strength

- Moderate

- Color

- Grey

- Thermal Conductivity

- 0.16 W/mK

- Material

- Autoclaved Aerated Concrete (AAC)

- Water Absorption

- 50-55%

- Length

- 600 mm

- Frost Resistance

- High

- Drying Shrinkage

- 0.04% (Max)

- Type

- Broken AAC Block

- Width

- 200 mm

- Dry Density Grade

- 550-650 kg/m

- Porosity

- High

- Weight

- 5-15 kg (Varies)

- Size

- 600x200x75-150 mm

- Shape

- Broken/Irregular

- Toxicity

- Non-toxic, safe for construction

- Eco-Friendliness

- Environmentally friendly; made from inorganic materials and recycled as broken pieces

- Fire Resistance

- Excellent, over 4 hours per IS standards

- Sound Insulation

- Good acoustic properties due to air pockets

- Reusability

- Suitable for secondary recycled use in construction works

- Chemical Resistance

- High, unaffected by pests, termites or fungus

- Surface Finish

- Rough, uneven texture (broken block nature)

- Packaging

- Loose or in bags/bulk as per order

- Market Supply Form

- Available in bulk, customizable as per site needs

- ISI Certified

- Yes, IS 2185 (Part 3) compliant

- Efflorescence

- Nil to very slight

Construction AAC Broken Blocks Trade Information

- Payment Terms

- Cash Against Delivery (CAD), Telegraphic Transfer (T/T), Cheque

- Sample Available

- Yes

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

About Construction AAC Broken Blocks

Features, Usage, and Application Spotlight

Construction AAC Broken Blocks display a brilliant combination of lightweight strength and eco-credentials, making them a preferred choice for demanding projects. Their rough texture and high porosity aid in sound insulation, while fire resistance ensures safety. Suited for landfilling, road sub-bases, filler works, and construction, these blocks triumph in secondary applications like drainage or ground work, providing a classic sustainable alternative for varied civil and infrastructure projects.

Premium Supply, Delivery, and FOB Details

Our AAC Broken Blocks are available in bulk, with the supply tailored to suit site requirements. Shipped Goods leave from our premium FOB Indian ports, ensuring smooth logistics and timely arrivals. The asking price varies on order volume and packaging preferencebagged or loose. With prompt delivery schedules and quality packaging, clients receive goods reliably for their projects, reinforcing our commitment as a leading manufacturer and supplier in the market.

FAQs of Construction AAC Broken Blocks:

Q: How are AAC Broken Blocks used in construction projects?

A: AAC Broken Blocks are used as filler material, for landfilling, sub-bases in road construction, and drainage works. Their robust properties make them ideal for secondary recycled use in various applications.Q: What makes AAC Broken Blocks a brilliant choice for eco-friendly construction?

A: These blocks are made entirely from inorganic and recycled materials, making them environmentally friendly. They are non-toxic, free from efflorescence, and highly resistant to chemicals, pests, and fungus.Q: Where can these blocks be applied apart from main wall construction?

A: Aside from structural applications, AAC Broken Blocks are widely used in landfilling, road sub-base layering, filler usage in cavities, and other foundational works due to their irregular shape and sound insulation features.Q: What is the fire resistance capability of these blocks?

A: AAC Broken Blocks offer excellent fire resistance, withstanding over four hours of exposure as per IS standards, making them a safe solution for a variety of construction needs.Q: How is the product supplied and what is the delivery process?

A: The blocks are supplied in bulk, either loose or in bags, directly from our premium Indian FOB port. Delivery times depend on the order volume, and every shipment is packaged as per client requirements to ensure safe and prompt delivery.Q: What are the main benefits of choosing broken AAC blocks over other materials?

A: Their high strength-to-weight ratio, eco-friendliness, reusability, superior fire and chemical resistance, and sound insulation make them a classic and reliable material for progressive construction practices.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in AAC Blocks Category

Magicrete AAC Blocks

Minimum Order Quantity : 100

Size : 600mm x 200mm x 100300mm

Shape : Rectangular

Moisture Content : Not More than 10%

Carbonation Coefficient : Negligible

Oftening Coefficient : 0.88

Lightweight Concrete Block

Minimum Order Quantity : 50 Bags

Size : 600x200x100/150 mm (typical)

Shape : Rectangular, Solid with possible Cavity

Moisture Content : <10%

Carbonation Coefficient : Low

Oftening Coefficient : 0.850.9

Building Hollow Blocks

Minimum Order Quantity : 10 Containers

Size : 400 x 200 x 100 mm

Shape : Rectangular

Moisture Content : <10%

Carbonation Coefficient : Low

Oftening Coefficient : >0.90

ACC Rectangular Blocks

Size : 600 mm x 200 mm x (75300 mm)

Shape : Rectangular

Moisture Content : 12%

Carbonation Coefficient : Low

Oftening Coefficient : 0.92

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS